Hollow Blocks

Fly-ash / Hollow Blocks:

MPPL is the single largest manufacturer of Baroda supplying hollow concrete blocks in all parts of Gujarat. Wide range of concrete blocks with large inventory provides flexibility and speed in construction to construction companies.

Compressive Strength 30 to 35 kg Cm2

Introduction:

Hollow concrete blocks are substitutes for conventional bricks and stones in building construction. They are lighter than bricks, easier to place and also confer economics in foundation cost and consumption of cement. In comparison to conventional bricks, they offer the advantages of uniform quality, faster speed of construction, lower labour involvement and longer durability. In view of these advantages, hollow concrete blocks are being increasingly used in construction activities.

Structural Advantages

In this construction system, structurally, each wall and slab behaves as a shear wall and a diaphragm respectively, reducing the vulnerability of disastrous damage to the Structure / building during the natural hazards.

Due to the uniform distribution of reinforcement in both vertical and horizontal directions, through each masonry element, increased tensile resistance and ductile behaviour of elements could be achieved. Hence, this construction system can safely resist lateral or cyclic loading, when compared to other conventional masonry construction systems. This construction system has also been proved to offer better resistance under dynamic loading, when compared to other conventional systems of construction.

Constructional Advantages

No additional formwork or any special construction machinery is required for reinforcing the hollow block masonry.

Only semi-skilled labour is required for this type of construction.

It is a faster and easier construction system, when compared to the other conventional construction systems.

It is also found to be a cost-effective disaster resistant construction system, as explained in the next section.

Architectural and Other Advantages

This construction system provides better acoustic and thermal insulation for the building.

This system is durable and maintenance free.

Reduction in Dead Load

Reduced Air Conducting Load: - Approx.50% saving.

No salt peter or leaching: - Reduction in maintenance.

Increased carpet area: - Due to smaller in size.

Faster construction: - Easy to work with bigger in size.

Assured Quality: - Fully automatic block plant.

Better sound absorption: - Being hollow in nature.

Reduced thickness of plaster: - Due to size accuracy & less cement consumption due to fewer joints.

Load bearing walls: - Due to higher strength of blocks.

Recommended for earth quake resistance.

Less water absorption:- Approx. 3 to 4%

Environmental Eco-Friendly

Reduce in total cost of project: - Being less dead load of walls.

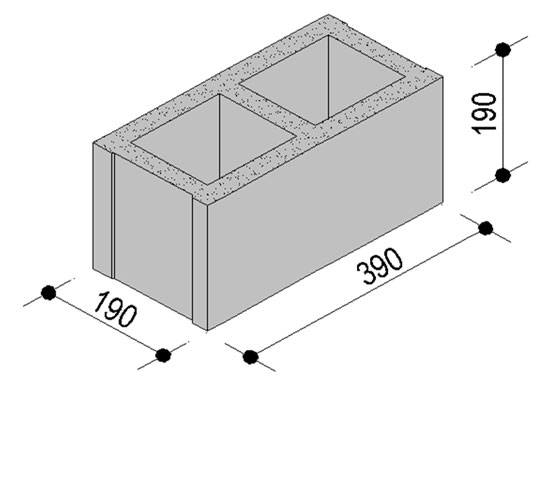

The standard sizes of hollow concrete blocks are –

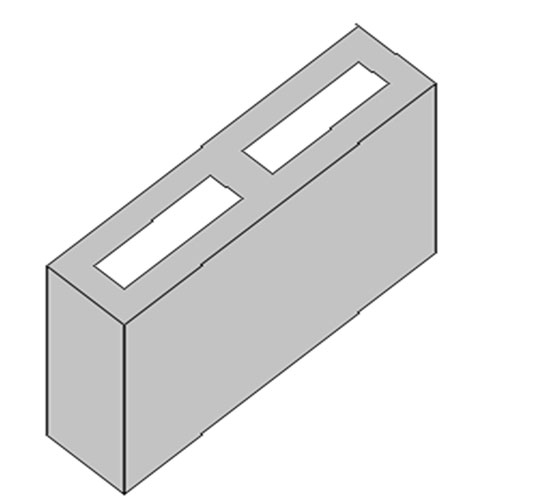

Hollow blocks with two cavity in each block

- (a) 400mm x 200mm x 200mm

- (b) 400mm x 200mm x 150mm

- (c) 400mm x 200mm x 100mm

Half Blocks

- (d) 200mm x 200mm x 200mm

- (e) 200mm x 200mm x 150mm

- (f) 200mm x 200mm x 100mm

MINAR PREFAB

MINAR PREFAB